Founder of Sprouting Gear Inc. Shows, How to Reduce the Carbon and Water Footprint of Cattle by 95%

Paul Pluss of Sprouting Gear shows how hydroponic barley fodder can cut cattle's water and carbon footprint by up to 95%—without ditching meat.

We don’t need to stop eating meat—we need to change how we feed livestock. Our system can reduce water use by up to 99% and carbon footprint by 95%, while cutting production costs.”

RAMONA, CA, UNITED STATES, June 24, 2025 /EINPresswire.com/ -- Sprouting Gear would like to present why Water should be of bigger concern than Carbon to every American and provide a possible solution. — Paul Pluss, Founder of Sprouting Gear Inc.

About 2/3rds of our agriculture is irrigated with aquifer water, described as “fossil water”, because scientists say they could take centuries to refill. Flooding rainstorms have little impact on the aquifers. Livestock accounts for over 60% of our water usage. Livestock ranks among the top five in terms of diesel fuel and electrical usage.

We don’t need to become vegan and stop eating meat, we need to change how we feed livestock, said Pluss.

Paul Pluss, founder of Sprouting Gear Inc., outlines how he believes he has solved the problems associated with the many attempts at indoor hydroponic vertical farming of food. Pluss says that there is one form of food that can be produced for significantly less than traditional dirt farmed crops. Barley has been selectively bred for thousands of years, grows incredibly fast, and can be produced hydroponically, as in its early grass stage, for livestock with at least 100 times less energy required for growth lighting than the amount needed for any food that people eat.

Lighting energy is the primary limitation of indoor climate controlled vertical farming, but the logistics of packaging and distribution of food for people is a carbon producing nightmare. These can be overcome when you feed livestock instead of people.

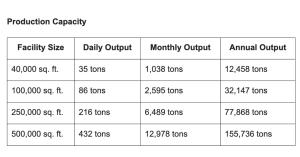

Pluss said, imagine a feed method that cuts water use by 95–99%, reduces land use by 95%, has a near-zero carbon footprint, improves feed digestibility, lowers total production costs, and opens up new carbon and water offset revenue streams that the farmer can profit from.

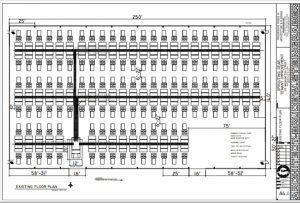

That’s what Pluss has spent years developing—a system that grows barley fodder hydroponically in large climate-controlled buildings with greater efficiency than ever before.

“Barley fodder” is made by sprouting seeds in trays using no soil, just nutrient enriched water it has an incredibly fast growth rate in the system Pluss designed, it grows into a dense mat of live grass and roots, which is 100% edible for livestock and it is packed with beneficial enzymes and probiotics. Unlike dry hay or silage, this is living feed—more natural and easier on a cow’s digestive system, with less methane suspected.

Pluss initially sold fodder equipment systems 8-10 years ago to small-scale farmers, but realized the economics didn’t work: fodder could not compete with the low cost of mass-produced hay—until now.

The Four-Part Solution, Cattle first: For maximum efficiency, we start by focusing solely on cattle sent to feedyards to be fattened prior to processing.

A high population of cattle adjacent to the farmland required for bulk seed production makes feedyards logistically the most efficient location to implement.

Step 1: Improve Yield and Efficiency

A few years ago, Pluss built a climate-controlled testing room with the goal of improving the growing process. Hundreds of trials and tests later, from equipment configuration and hydroponic nutrient solutions, he has achieved triple the yield from seed to feed of prior systems, with significant gains in yield-per-square-foot and far less labor.

Step 2: Cut Out Transport, equipment, Diesel usage, and multiple levels of profit taking.

Traditional feed requires multiple machines and trucks to grow, harvest, stack, load, and deliver feed—making livestock one of the top five users of diesel fuel worldwide.

With Sprouting Gear Inc.’s (SGI) plan, fodder warehouses are built right next to feedyards.

To produce the bulk seed for growing the fodder, barley will be traditionally farmed near the building. You only need about 5% of the land for the seed that is replacing the hay or corn. Barley is drought-tolerant and can be dry-farmed with just seasonal rainfall.

The building acts as a feed multiplier, converting one ton of seed into nine tons of fresh live fodder.

With these steps, you reduce about 99% of transportation costs, 95% less of the diesel fuel, equipment, and skilled labor, and you produce the bulk seed for growing the fodder without any electricity, pumping water from the aquifer’s rivers or lakes.

Step 3: The grow building water and carbon. With the previous steps, you now have the seed siloed next to the fodder building for growing. You produced it without irrigation water, and it will result in about a 95% reduction in carbon compared to the hay or corn it will replace. The growing buildings are designed to produce no wastewater, not even through evaporation loss. The only water that exits the building is in the blades and roots of the fodder.

For the power requirements of the building, calculations show that just 1/3 of the roof in solar panels offsets the grow lighting, and 1/3rd covers the climate control for a near net-zero carbon footprint for the fodder.

Step 4: Offset Revenue Opportunities With such drastic reductions in water, fuel, and electrical use, feedyard operations using SGI’s system can likely qualify for both water and carbon offsets—like how Tesla has earned over $10.7 billion from carbon offsets.

Now for the math of water reduction:

Of the top ten water hogging crops Alfalfa tops the list, documented at about 570,000 gallons of water per ton of hay produced. Alfalfa is the most widely grown crop in the U.S. Grass hay is second, and feed corn ranks third among the most water-intensive crops.

Cattle eating fodder consume more by weight—up to three times more than dry feed—due to fodder's water content, so if 75% of the fodder is in water weight, that calculates to 180 gallons of water per ton of fodder.

So, if you are to feed three tons of fodder that requires 540 gallons of water, it is equivalent to replacing one ton of alfalfa that requires 570,000 gallons. That is 99% less water.

For more information, visit www.sproutinggear.com or contact Paul Pluss at Paul@sproutinggear.com.

Paul Pluss

Sprouting Gear

info@sproutinggear.com

Visit us on social media:

LinkedIn

YouTube

Instagram

Facebook

Why Steak Prices Are So High | The Hidden Crisis in U.S. Cattle Farming

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.